Fan balancing machines

- Балансировка вентиляторов центробежных

- Балансировка рабочего колеса вентилятора

- Балансировка центробежного вентилятора

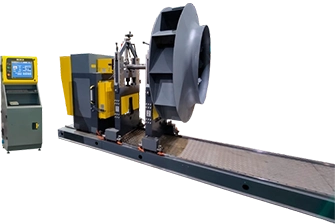

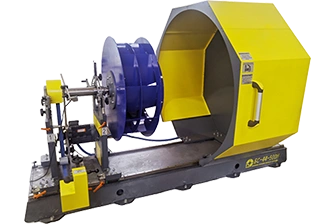

- Балансировочный станок для вентилятора (турбины) внутреннего блока кондиционера

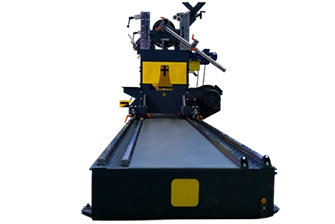

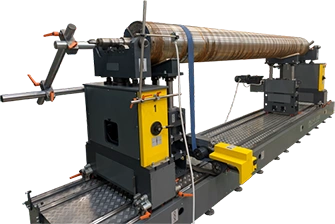

- Балансировочный станок для дымососа, вентилятора

- Балансировочный станок для крыльчаток вентиляции

- Балансировочный станок для промышленных вентиляторов

- Балансировочный станок для рабочего колеса вентилятора

- Балансировочный станок для рабочих колес вентилятора

- Балансировочный станок крыльчаток вентиляции

Balancing machine for fans is specialized equipment designed to detect and eliminate imbalance in fan rotors, impellers and other rotating parts. Balancing helps reduce vibration, decrease bearing load and improve ventilation equipment reliability.

Most Applicable

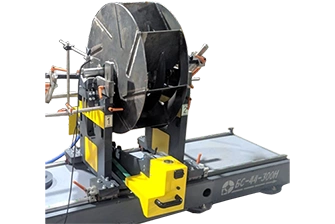

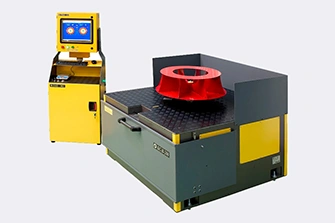

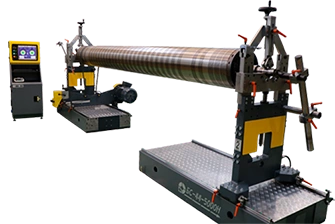

BS-44-500H

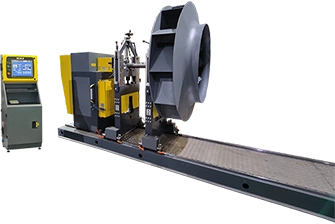

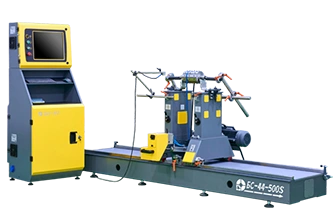

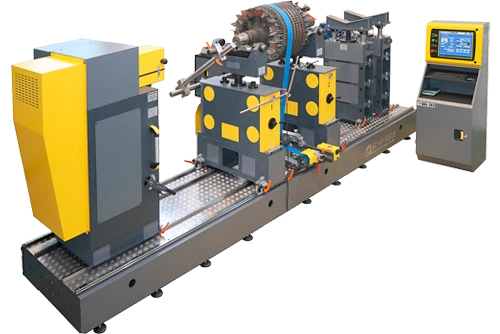

BS-44-3000H

Might Suit Your Tasks

| Rotor weight to be balanced, kg | Rotor diameter to be balanced, mm | Distance between rotor journal centers, mm | Rotor journal diameter, mm | Minimum achievable residual unbalance | Drive power, kW | Drive type | Machine dimensions L×H×W, mm | Mechanical part weight (with standard bed), kg | Power supply voltage V/Hz/Phases | |

|---|---|---|---|---|---|---|---|---|---|---|

| BS-24-5H | 0,02 - 5 | 5-420 | 15-350 | 5-30 | 0,05 | 0,09 | Belt | 440х400х800 | 47 | 220/50/1 |

| BS-24-8H | 0,02 - 10 | 5-400 | 20-550 | 5-30 | 0,05 | 0,37 | Belt | 670х420х360 | 68 | 220/50/1 |

| BS-24-20H | 0,02 - 20 | 5-420 | 20-550 | 5-32 | 0,05 | 0,37 | Belt | 670х420х360 | 73 | 220/50/1 |

| BS-34-50H | 0,2 - 60 | 1040 * | 20-1260 * | 11-160 | 0,05 | 0,75 | Belt / Cardan / Combined | 1550х1100х800 | 610 | 380/50/3 |

| BS-34-50S | 0,2 - 60 | 1000 * | 20-1200 * | 12-160 | 0,05 | 0,75 | Belt / Cardan / Combined | 1550х1100х800 | 590 | 380/50/3 |

| BS-34-100H | 0,5 - 150 | 1070 * | 20-1450 * | 10-170 | 0,05 | 1,1 | Belt / Cardan / Combined | 1700х1100х820 | 770 | 380/50/3 |

| BS-34-100S | 0,5 - 150 | 1000 * | 20-1400 * | 12-160 | 0,05 | 1,1 | Belt / Cardan / Combined | 1700х1100х820 | 690 | 380/50/3 |

| BS-34-200H | 0,5 - 200 | 1070 * | 20-1450 * | 10-170 | 0,05 | 1,5 | Belt / Cardan / Combined | 1700х1100х820 | 790 | 380/50/3 |

| BS-34-200S | 0,5 - 200 | 1000 * | 20-1200 * | 12-160 | 0,05 | 1,5 | Belt / Cardan / Combined | 1700х1100х820 | 750 | 380/50/3 |

| BS-44-300H | 1,6 - 400 | 1500 * | 10/80-1700 * | 15-190 | 0,05 | 4,0 | Belt / Cardan / Combined | 2000х1200х1200 | 680 | 380/50/3 |

| BS-44-300S | 1,6 - 400 | 1600 * | 10/80-1650 * | 12-140 | 0,05 | 4,0 | Belt / Cardan / Combined | 2000х1200х1200 | 630 | 380/50/3 |

| BS-44-500H | 3 - 700 | 1500 * | 10/80-1700 * | 20-180 | 0,05 | 5,5 | Belt / Cardan / Combined | 2000х1200х1200 | 790 | 380/50/3 |

| BS-44-500S | 5 - 600 | 1600 * | 10/80-1650 * | 12-140 | 0,05 | 5,5 | Belt / Cardan / Combined | 2000х1200х1200 | 740 | 380/50/3 |

| BS-44-1000H | 5 - 1500 | 1700 * | 30/120 - 1650 * | 20-230 | 0,1 | 11,0 | Belt / Cardan / Combined | 2000х1400х1400 | 1170 | 380/50/3 |

| BS-44-1000S | 5 - 1500 | 1850 * | 30/120 - 1550 * | 15-250 | 0,1 | 11,0 | Belt / Cardan / Combined | 2000х1400х1400 | 1085 | 380/ 50/ 3 |

| BS-44-3000H | 16 - 4000 | 2400 * | 30/135 - 1500 * | 25-270 | 0,1 | 18,5 | Belt / Cardan / Combined | 2000х1600х1400 | 1900 | 380/ 50/ 3 |

| BS-44-3000S | 16 - 4000 | 2300 * | 30/135 - 1480 * | 20-290 | 0,1 | 18,5 | Belt / Cardan / Combined | 2000х1600х1400 | 1799 | 380/ 50/ 3 |

| BS-44-5000H | 30 - 6000 | 2400 * | 40/140 - 3500 * | 20-300 | 0,2 | 22,0 | Belt / Cardan / Combined | 2000х1750х1400 | 2150 | 380/ 50/ 3 |

| BS-44-5000S | 30 - 6000 | 2250 * | 40/140 - 3400 * | 20-350 | 0,2 | 22,0 | Belt / Cardan / Combined | 2000х1750х1400 | 2050 | 380/ 50/ 3 |

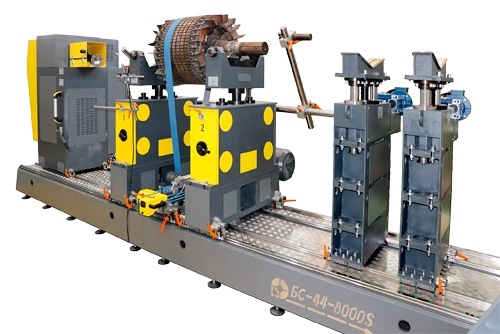

| BS-44-8000H | 30 - 8000 | 2850 * | 65/250-5700 * | 20-310 | 0,25 | 30,0 | Belt / Cardan / Combined | 4000х1700х1900 | 4150 | 380/ 50/ 3 |

| BS-44-8000S | 30 - 8000 | 2750 * | 65/250-5650 * | 20-400 | 0,25 | 30,0 | Belt / Cardan / Combined | 4000х1700х1900 | 3980 | 380/ 50/ 3 |

| BS-44-10000H | 80 - 10000 | 2850 * | 70/280-5700 * | 20-310 | 0,25 | 37,0 | Belt / Cardan / Combined | 4000х1700х2000 | 4350 | 380/ 50/ 3 |

| BS-44-10000S | 50 - 10000 | 2750 * | 70/280-5650 * | 20-400 | 0,25 | 37,0 | Belt / Cardan / Combined | 4000х1700х2000 | 4250 | 380/ 50/ 3 |

| BS-44-20000H | 100 - 20000 | 2850 * | 5650 * | 25-500 | 0,4 | 55 | Belt / Cardan / Combined | 7000х2200х2000 | 6550 | 380/ 50/ 3 |

| BS-44-20000S | 1000 - 20000 | 2750 * | 5400 * | 25-500 | 0,4 | 55 | Belt / Cardan / Combined | 7000х2200х2000 | 6230 | 380/ 50/ 3 |

| BS-В-10 | 0,5 - 10 | up to 600 | 0.2 | 0,55 | 500х1500х650 | 180 | 380/50/3 | |||

| BS-В-20 | 1,0 - 20 | up to 600 | up to 0.5 | 0,75 | 750х750х800 | 240 | 380/50/3 | |||

| BS-В-60 | 1,0 - 65 | up to 800 | up to 0.5 | 2,2 | 1100х1100х1250 | 540 | 380/50/3 | |||

| BS-В-200 | 1,0 - 200 | up to 1000 | up to 1 | 5,5 | 1200х1200х850 | 1750 | 380/50/3 | |||

| BS-В-600 | 5,0 - 600 | up to 1300 | до 2 | 11 | 1430х1430х890 | 2340 | 380/50/3 | |||

| BS-44-1250 | 5 - 300 | 100-1250 | 0,3 | 18,5 | Direct | 1500х1200х800 | 700 | 380V/50 Hz/3 phases |

The table contains data related to the standard machine configuration. Most parameters can be modified upon customer request.

Fan Balancing Machines

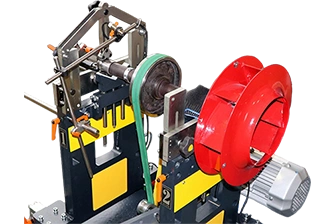

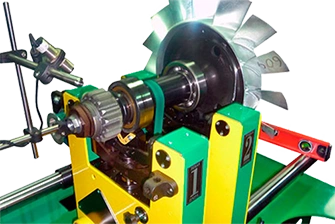

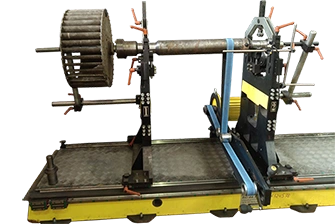

The performance of ventilation or other air handling equipment directly depends on the stability and efficient operation of impellers, which are a key component of fans responsible for moving air and creating airflow in various systems. The productivity of the entire ventilation system hinges on them, whether it's industrial exhaust units, cooling systems, or air conditioning systems.

Over time or due to manufacturing situations, fan impellers can become unbalanced. Even a slight imbalance can lead to serious consequences: increased vibration, elevated noise levels, reduced fan efficiency, and accelerated wear of bearings and other components. This, in turn, leads to frequent breakdowns and reduced equipment lifespan.

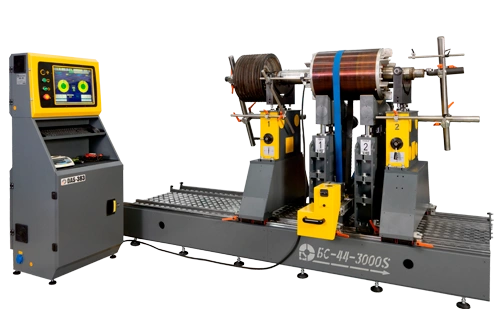

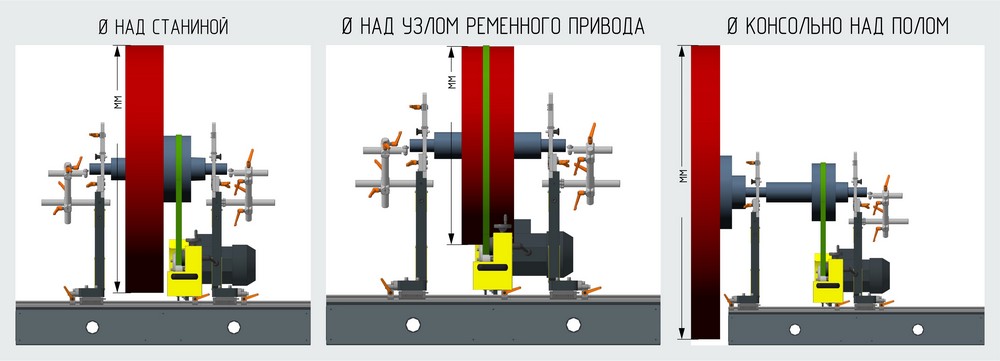

To prevent such emergency situations, manufacturing enterprises can use horizontal balancing machines, which allow for precise diagnosis and elimination of imbalance on various fan impellers. The machines from Robals LLC are used both in manufacturing plants and in repair shops where ventilation systems are serviced and restored. They ensure high balancing accuracy, which is especially important for industrial fans operating under demanding conditions.

Horizontal balancing stands designed for diagnosing and correcting impeller imbalance address the task of extending the service life of existing equipment during its operation in production. Imbalance can occur at various stages of equipment operation: from initial manufacturing defects to the natural wear and tear of components. Fans, especially those used in industrial settings, are subject to significant loads, making their regular maintenance and balancing extremely necessary. The primary purpose of these machines is to provide precise and efficient balancing of impellers of various sizes and types. In repair shops, the machines allow not only for diagnosing the condition of impellers but also for restoring their original characteristics, thereby extending the equipment's service life. Various methods are used for this, from adding or removing material on the blades to installing additional balancing weights.

In manufacturing environments, horizontal balancing machines are used to check the quality of new impellers, identify potential deviations from specified parameters, and, if necessary, correct them until full balance is achieved. This is particularly important in the production of large-sized fans, where even a minimal imbalance can lead to significant operational problems.

The horizontal balancing machines from Robals LLC have a number of features that make them indispensable in the process of balancing fan impellers. The main and key characteristic of these machines is high measurement accuracy. Thanks to modern sensors and a proprietary analysis system, the machines can detect even the slightest deviations in the impeller's mass distribution, which is especially important for large industrial fans.

The technologies used in our balancing machines are based on the integration of mechanical and digital systems. This allows the operator not only to perform diagnostics but also to receive instant recommendations for imbalance correction. For example, the machine can indicate the exact points on the impeller where material needs to be added or removed to achieve perfect balance. Such automation of the process significantly simplifies the work and minimizes the human factor, which is particularly important in mass production.

Another feature characterizing our machines is their versatility. They can work with impellers of various sizes and designs. This allows the same machine to be used in both manufacturing and repair shops, servicing a wide range of fans, from small household models to large industrial systems. Depending on the configuration, the machine can be equipped with various tooling to adapt it to specific tasks.

The use of our machines provides significant advantages for production:

- Time and Resource Savings. Due to high data processing speed and automatic imbalance correction, the balancing process becomes faster and more efficient.

- Reduction of Operating Costs, as precise balancing prevents premature wear of fan components and reduces the likelihood of failures.

- Increased Overall Equipment Reliability and Productivity, which is especially important under conditions of intensive use.

Innovations in the software of Robals LLC machines have also enhanced their efficiency. The modern analysis system can store data from previous balancing sessions, allowing for tracking changes in equipment condition over time and responding promptly to emerging problems. This is especially useful for companies managing large fleets of fans, where constant monitoring of equipment condition is necessary.

When selecting a machine, consider its technical specifications, as they directly affect the machine's capabilities and its field of application. This primarily concerns parameters such as the mass range the machine can handle, its measurement accuracy, and the impeller rotation speed during balancing. All these characteristics determine which specific impellers can be serviced on the machine and how effective the balancing process will be.

One of the key parameters is the mass range. Depending on the machine model, it can range from a few kilograms to several tons. This allows the machines to be used for balancing small impellers used in household fans, as well as for servicing large industrial units. The wider the range, the more versatile the machine, and the more diverse tasks it can handle.

The balancing machines from Robals LLC are equipped with highly sensitive sensors capable of detecting even minimal deviations from the norm. This accuracy is necessary, especially when the impeller operates at high speeds or under increased loads. For industrial fans, where reliability and durability are paramount, high balancing accuracy is a critical requirement.

The impeller rotation speed on the machine is also important for the balancing process. It can be adjusted depending on the type and size of the impeller, as well as the requirements for measurement accuracy. The optimal rotation speed allows for... If you have difficulty choosing a machine, contact our managers to clarify the model suitable for your tasks.