Rotor balancing machines

| Rotor weight to be balanced, kg | Rotor diameter to be balanced, mm | Distance between rotor journal centers, mm | Rotor journal diameter, mm | Minimum achievable residual unbalance | Drive power, kW | Drive type | Machine dimensions L×H×W, mm | Mechanical part weight (with standard bed), kg | Power supply voltage V/Hz/Phases | |

|---|---|---|---|---|---|---|---|---|---|---|

| BS-24-5H | 0,02 - 5 | 5-420 | 15-350 | 5-30 | 0,05 | 0,09 | Belt | 440х400х800 | 47 | 220/50/1 |

| BS-24-8H | 0,02 - 10 | 5-400 | 20-550 | 5-30 | 0,05 | 0,37 | Belt | 670х420х360 | 68 | 220/50/1 |

| BS-24-20H | 0,02 - 20 | 5-420 | 20-550 | 5-32 | 0,05 | 0,37 | Belt | 670х420х360 | 73 | 220/50/1 |

| BS-34-50H | 0,2 - 60 | 1040 * | 20-1260 * | 11-160 | 0,05 | 0,75 | Belt / Cardan / Combined | 1550х1100х800 | 610 | 380/50/3 |

| BS-34-50S | 0,2 - 60 | 1000 * | 20-1200 * | 12-160 | 0,05 | 0,75 | Belt / Cardan / Combined | 1550х1100х800 | 590 | 380/50/3 |

| BS-34-100H | 0,5 - 150 | 1070 * | 20-1450 * | 10-170 | 0,05 | 1,1 | Belt / Cardan / Combined | 1700х1100х820 | 770 | 380/50/3 |

| BS-34-100S | 0,5 - 150 | 1000 * | 20-1400 * | 12-160 | 0,05 | 1,1 | Belt / Cardan / Combined | 1700х1100х820 | 690 | 380/50/3 |

| BS-34-200H | 0,5 - 200 | 1070 * | 20-1450 * | 10-170 | 0,05 | 1,5 | Belt / Cardan / Combined | 1700х1100х820 | 790 | 380/50/3 |

| BS-34-200S | 0,5 - 200 | 1000 * | 20-1200 * | 12-160 | 0,05 | 1,5 | Belt / Cardan / Combined | 1700х1100х820 | 750 | 380/50/3 |

| BS-44-300H | 1,6 - 400 | 1500 * | 10/80-1700 * | 15-190 | 0,05 | 4,0 | Belt / Cardan / Combined | 2000х1200х1200 | 680 | 380/50/3 |

| BS-44-300S | 1,6 - 400 | 1600 * | 10/80-1650 * | 12-140 | 0,05 | 4,0 | Belt / Cardan / Combined | 2000х1200х1200 | 630 | 380/50/3 |

| BS-44-500H | 3 - 700 | 1500 * | 10/80-1700 * | 20-180 | 0,05 | 5,5 | Belt / Cardan / Combined | 2000х1200х1200 | 790 | 380/50/3 |

| BS-44-500S | 5 - 600 | 1600 * | 10/80-1650 * | 12-140 | 0,05 | 5,5 | Belt / Cardan / Combined | 2000х1200х1200 | 740 | 380/50/3 |

| BS-44-1000H | 5 - 1500 | 1700 * | 30/120 - 1650 * | 20-230 | 0,1 | 11,0 | Belt / Cardan / Combined | 2000х1400х1400 | 1170 | 380/50/3 |

| BS-44-1000S | 5 - 1500 | 1850 * | 30/120 - 1550 * | 15-250 | 0,1 | 11,0 | Belt / Cardan / Combined | 2000х1400х1400 | 1085 | 380/ 50/ 3 |

| BS-44-3000H | 16 - 4000 | 2400 * | 30/135 - 1500 * | 25-270 | 0,1 | 18,5 | Belt / Cardan / Combined | 2000х1600х1400 | 1900 | 380/ 50/ 3 |

| BS-44-3000S | 16 - 4000 | 2300 * | 30/135 - 1480 * | 20-290 | 0,1 | 18,5 | Belt / Cardan / Combined | 2000х1600х1400 | 1799 | 380/ 50/ 3 |

| BS-44-5000H | 30 - 6000 | 2400 * | 40/140 - 3500 * | 20-300 | 0,2 | 22,0 | Belt / Cardan / Combined | 2000х1750х1400 | 2150 | 380/ 50/ 3 |

| BS-44-5000S | 30 - 6000 | 2250 * | 40/140 - 3400 * | 20-350 | 0,2 | 22,0 | Belt / Cardan / Combined | 2000х1750х1400 | 2050 | 380/ 50/ 3 |

| BS-44-8000H | 30 - 8000 | 2850 * | 65/250-5700 * | 20-310 | 0,25 | 30,0 | Belt / Cardan / Combined | 4000х1700х1900 | 4150 | 380/ 50/ 3 |

| BS-44-8000S | 30 - 8000 | 2750 * | 65/250-5650 * | 20-400 | 0,25 | 30,0 | Belt / Cardan / Combined | 4000х1700х1900 | 3980 | 380/ 50/ 3 |

| BS-44-10000H | 80 - 10000 | 2850 * | 70/280-5700 * | 20-310 | 0,25 | 37,0 | Belt / Cardan / Combined | 4000х1700х2000 | 4350 | 380/ 50/ 3 |

| BS-44-10000S | 50 - 10000 | 2750 * | 70/280-5650 * | 20-400 | 0,25 | 37,0 | Belt / Cardan / Combined | 4000х1700х2000 | 4250 | 380/ 50/ 3 |

| BS-44-20000H | 100 - 20000 | 2850 * | 5650 * | 25-500 | 0,4 | 55 | Belt / Cardan / Combined | 7000х2200х2000 | 6550 | 380/ 50/ 3 |

| BS-44-20000S | 1000 - 20000 | 2750 * | 5400 * | 25-500 | 0,4 | 55 | Belt / Cardan / Combined | 7000х2200х2000 | 6230 | 380/ 50/ 3 |

| BS-В-10 | 0,5 - 10 | up to 600 | 0.2 | 0,55 | 500х1500х650 | 180 | 380/50/3 | |||

| BS-В-20 | 1,0 - 20 | up to 600 | up to 0.5 | 0,75 | 750х750х800 | 240 | 380/50/3 | |||

| BS-В-60 | 1,0 - 65 | up to 800 | up to 0.5 | 2,2 | 1100х1100х1250 | 540 | 380/50/3 | |||

| BS-В-200 | 1,0 - 200 | up to 1000 | up to 1 | 5,5 | 1200х1200х850 | 1750 | 380/50/3 | |||

| BS-В-600 | 5,0 - 600 | up to 1300 | до 2 | 11 | 1430х1430х890 | 2340 | 380/50/3 | |||

| BS-44-1250 | 5 - 300 | 100-1250 | 0,3 | 18,5 | Direct | 1500х1200х800 | 700 | 380V/50 Hz/3 phases |

The table contains data related to the standard machine configuration. Most parameters can be modified upon customer request.

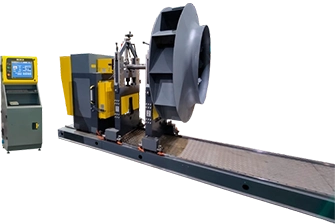

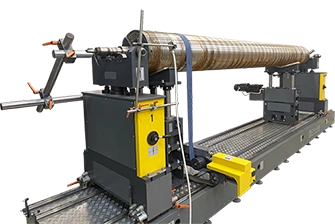

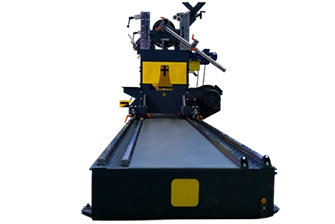

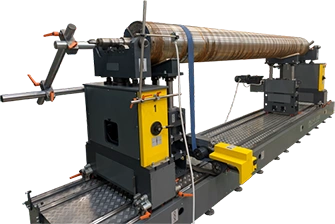

Rotor Balancing Machines

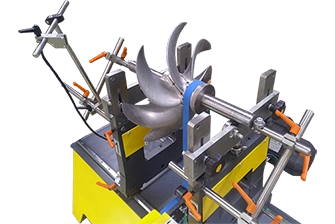

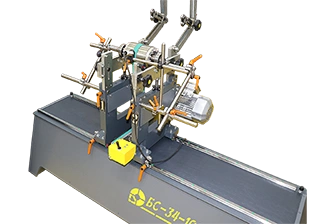

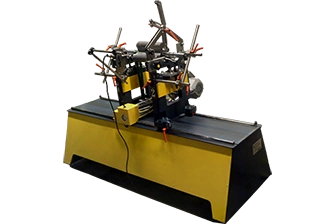

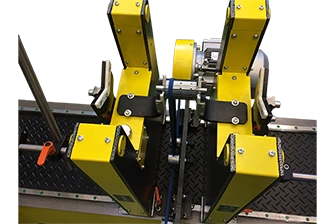

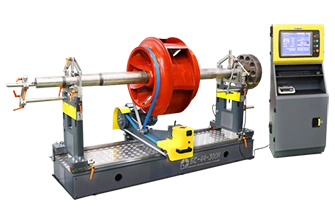

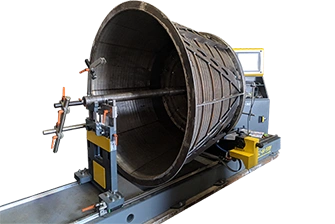

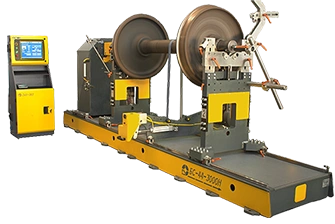

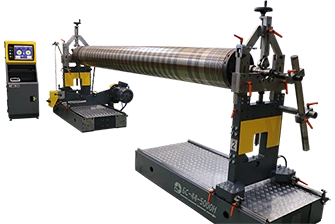

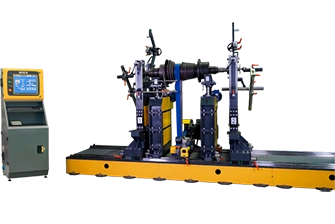

Universal horizontal balancing machines are designed for performing precise balancing of various types of rotors. Their characteristics enable them to handle a wide range of rotors – from small ones, such as electric motor rotors or automotive turbocharger rotors, to large ones, such as gas turbine and generator rotors. The machine design ensures a stable position of the rotor being balanced in the horizontal plane, providing high operational accuracy. Unlike vertical models, where the final result of unbalance correction can be influenced by gravitational forces or the human factor, such as improper clamping, horizontal machines clamp and hold parts more securely. This is especially important when working with large, heavy, or long rotors. Situations where the slightest misalignment can lead to balancing errors are eliminated.

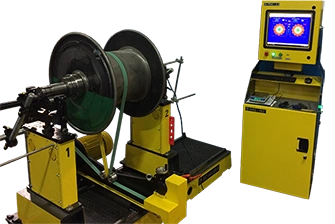

LLC "Robals" manufactures balancing machines for rotors with various purposes and different mounting methods. Our range allows for flexible configuration of production processes and work with diverse types of parts. The stands we produce are suitable for use in various industries, including the automotive industry, agricultural and power engineering. Therefore, despite the universality of our equipment, it is especially important to consider their features and characteristics at the time of selection. One of them is the selection of machine parameters depending on the dimensions of the rotors being processed. For example, high-speed rotors require equipment with increased accuracy, while for large and heavy units, stability and the ability to handle heavy weight are important. Solving these tasks requires not only the correct choice of the machine model but also qualified personnel capable of competently utilizing all the equipment's capabilities.

The technical characteristics of the machine determine its effectiveness in specific production conditions. One of the key parameters is balancing accuracy. It is achieved through the use of modern measurement and analysis systems developed by Robals specialists. These systems instantly and accurately record deviations in indicators and transmit data to the control module, allowing for prompt balancing correction and even distribution of mass across the rotor surface. For some types of parts, such as turbine rotors, balancing accuracy is particularly critical, as even a slight unbalance can lead to emergency situations.

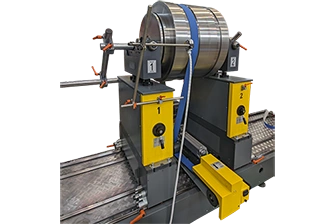

Another parameter to pay attention to is the range of rotor sizes and weights that can be balanced on the machine. Our rotor balancing machines are designed to handle weights from a few kilograms to several tons. Such versatility allows the same equipment to be used in different production workshops and on various lines, which is economically feasible, especially in production environments with a diverse product range.

All machines also support work with various types of rotors, including cylindrical, eccentric, and multi-layer designs. Special tooling and adaptive control systems implemented in LLC "Robals" machines allow for efficient work with any type of rotor, ensuring high accuracy and stability of results.

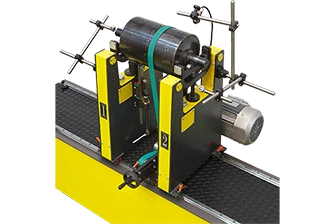

When choosing a machine, it is important to consider that there are two types of balancing machines: sub-resonant and super-resonant. Sub-resonant models operate at rotational frequencies below resonance and are suitable for balancing small and medium-sized rotors. They provide high stability and accuracy. Super-resonant models operate at rotational frequencies above resonance, allowing for effective balancing of heavy and large rotors, where accuracy and stability are particularly important.

We place special emphasis on the importance of automating balancing processes and incorporate the use of a wide range of additional options into the design of LLC "Robals" machines. The software equipped on these machines ensures ease of operation and allows for prompt unbalance correction. Correction can be performed in several ways: by adding or removing weight at specific points on the rotor, or through mechanical processing – by removing excess material. When additional equipment is installed, these processes can be automated, which is particularly useful in mass production, where human factor errors can lead to delays or defects.