DESCRIPTION

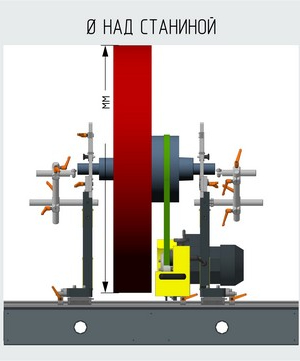

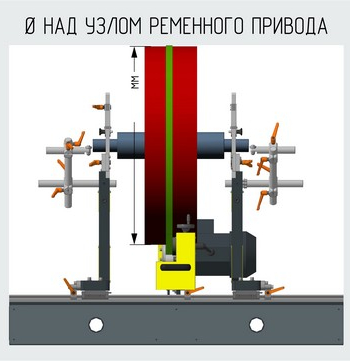

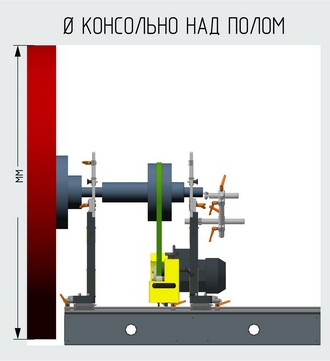

A universal horizontal-axis balancing machine designed for serial precision dynamic balancing of miniature rotors, such as power tool motor armatures, automotive turbines, small magnetic motors, as well as almost any rotors, assemblies, and parts that meet the weight and size requirements.

Efficient and high-quality balancing is ensured by the advanced design, quality of construction, and modern computer signal processing algorithm.

Technical Specifications of the Balancing Machine

Depending on the tasks, each machine can be equipped with additional tooling.

Warranty period extended to 24 months. Constant availability of main components in stock.

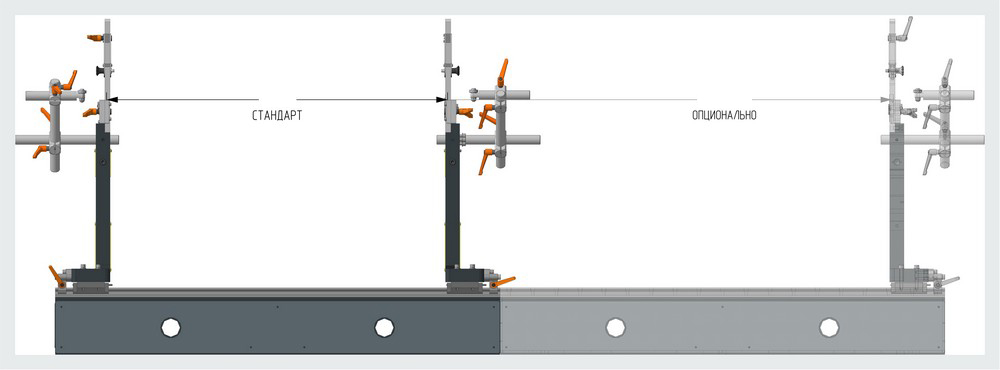

The machine can be supplied with a special base.

Application

Advantages

- Minimum achievable residual imbalance of 0.05 g*mm/kg.

- Imbalance reduction of up to 95% in a single run.

- Highest linearity of readings across all speed ranges and imbalance levels.

- Imbalance determination without trial runs for most rotors.

- Record-fast changeover from one rotor size to another.

- Easy balancing of overhung and double-overhung rotors, even with the center of gravity located outside the supports.

- Long-lasting support rollers with surface hardness of 60 HRC on SKF bearings.

- Excellent, time-tested design refined over years of production, incorporating vast operational experience across all industries and requiring minimal maintenance.

- High-quality European industrial hardware—everything features hand-operated levers. Virtually no tools are needed for setup and operation.

Software

The "R-Bal V3.9" software, like the hardware, is developed by "PK Robals" LLC and is continuously improved. It features a simple, intuitive interface.

Launch and Dynamic Balancing Skills Training

When purchasing a balancing machine, we provide two types of commissioning services: an on-site visit by a commissioning engineer and remote machine startup.

A modern balancing machine is complex equipment, and in conditions of a shortage of qualified personnel, high-quality specialist training is especially important. Therefore, we provide assistance in personnel training. During the training of a balancing machine operator, skills for working with the machine and the principles of rotor dynamic balancing are transferred.

An excellent reference tool for the machine operator is the "Balance Guide: Multimedia Course for Preparation to Work on a Balancing Machine" program. The media course consists of a series of videos that provide a brief description of terms used in the balancing process, describe types of rotors, causes and types of imbalance, main correction methods, outline safety measures when working with the machine, principles of interaction with the machine components, and describe all the functions of the software that controls the balancing machine.

The program can be used to review knowledge acquired during the commissioning works.