DESCRIPTION

A universal horizontal-axis balancing machine designed for dynamic balancing of components such as large-sized electric motor armatures, fans, centrifuges, pumps, train wheel sets, textile shafts, turbines, rubber pressure rollers, centrifugal impellers, drying cylinders, as well as almost any rotors, assemblies, and parts that meet the weight and size requirements.

Efficient and high-quality balancing is ensured by the advanced design, quality of construction, and modern computer signal processing algorithm. The machine has been in serial production for many years, is reliable, and maintainable.

Technical Specifications of the Balancing Machine

** Belt drive unit mounted behind the supports / Belt drive unit between the supports.

*** Machine length can also be reduced.

Most parameters can be modified according to customer requirements.

Application

Advantages

- Minimum achievable residual unbalance: 0.25 g*mm/kg.

- Unbalance reduction of up to 95% in a single run.

- Highest measurement linearity across all speed ranges and unbalance levels.

- Unbalance measurement without calibration runs for most rotors.

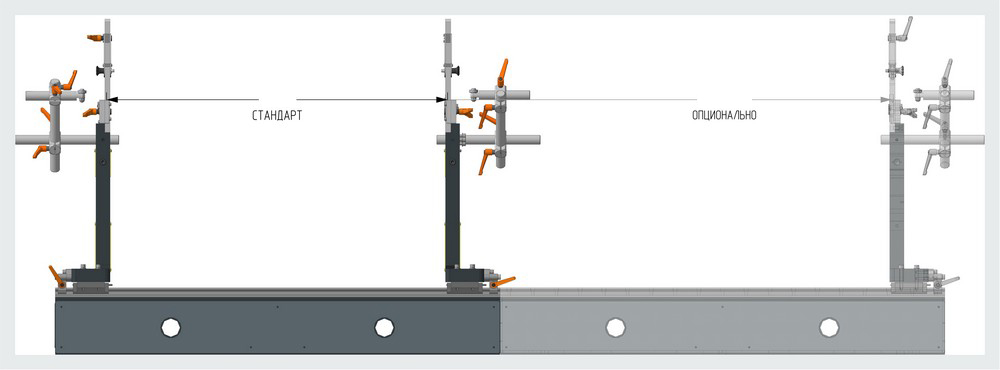

- Stands with 2 bearing blocks each, mounted on hardened and ground rail guides, providing more than a 12-fold safety margin for strength while allowing easy manual movement of the stand without any tools or mechanisms.

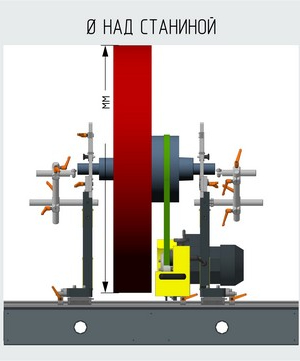

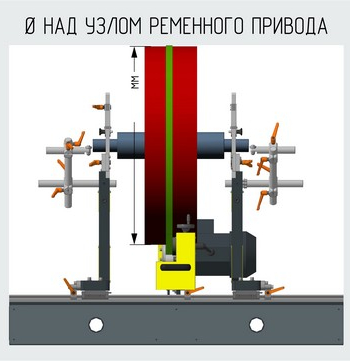

- Roller blocks and cradles feature a V-shaped design, allowing for balancing rotors in their own bearings.

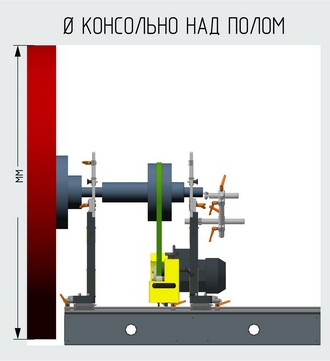

- Cantilevered positioning of rollers both within the roller block and the possibility of external remounting to tackle the most challenging balancing tasks.

- Air pressure adjustment, pressure gauge, and the belt tensioning system control lever are combined into a single unit.

- Record-fast changeover from one rotor size to another.

- Easy balancing of overhung and double-overhung rotors, even those with a center of gravity located outside the supports.

- Durable support rollers with a surface hardness of 60 HRC on SKF bearings.

- An excellent, time-tested design refined over years of manufacturing, incorporating extensive operational experience across all industries and requiring minimal maintenance.

- Unmatched versatility.

- Quick and easy to master.

- High-quality European industrial hardware — all handles. Virtually no tools needed for setup and operation.

- Reliable, rigid, and vibration-damping bed with a non-slip coating.

- Capability to balance rotors with a high initial unbalance.

- Convenient and practical adjustable cradles/jacks for smoothly transferring the rotor's weight onto the machine's rollers.

- An asynchronous frequency-controlled drive provides smooth, stepless speed variation and extensive options for selecting acceleration/deceleration modes.

- Simple and effective adjustment of the roller block height using the included ratchet wrench.

Software

The "R-Bal V3.9" software, like the hardware, is developed by "PK Robals" LLC and is continuously improved. It features a simple, intuitive interface.

Launch and Dynamic Balancing Skills Training

When purchasing a balancing machine, we provide two types of commissioning services: an on-site visit by a commissioning engineer and remote machine startup.

A modern balancing machine is complex equipment, and in conditions of a shortage of qualified personnel, high-quality specialist training is especially important. Therefore, we provide assistance in personnel training. During the training of a balancing machine operator, skills for working with the machine and the principles of rotor dynamic balancing are transferred.

An excellent reference tool for the machine operator is the "Balance Guide: Multimedia Course for Preparation to Work on a Balancing Machine" program. The media course consists of a series of videos that provide a brief description of terms used in the balancing process, describe types of rotors, causes and types of imbalance, main correction methods, outline safety measures when working with the machine, principles of interaction with the machine components, and describe all the functions of the software that controls the balancing machine.

The program can be used to review knowledge acquired during the commissioning works.