Technical Specifications of the Balancing Machine

Application

Advantages

- The vertical axis of rotation allows for maximum speed in changing workpieces during serial balancing.

- A set of adapters for the most common mounting diameters can be supplied with the machine.

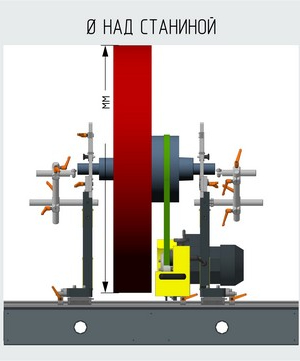

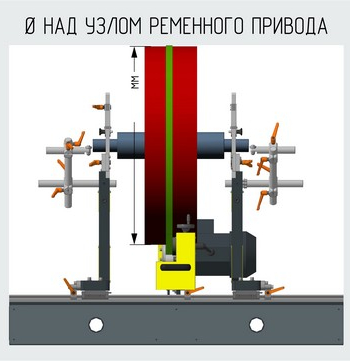

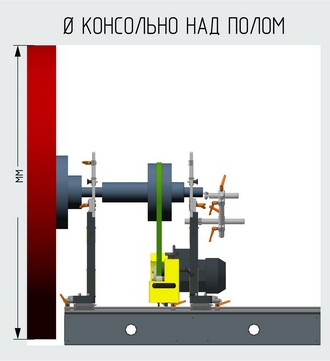

- Standard protective guard to ensure operator safety during balancing.

- Welding operations can be performed directly on the machine.

- Retrofitting with a drilling unit for imbalance correction directly on the machine is possible.

- All balancing machines are supplied with a high-quality vibration-damping base, allowing installation on a regular concrete floor. In rare cases, machine anchoring may be required.

Software

The "R-Bal V3.9" software, like the hardware, is developed by "PK Robals" LLC and is continuously improved. It features a simple, intuitive interface.

Launch and Dynamic Balancing Skills Training

When purchasing a balancing machine, we provide two types of commissioning services: an on-site visit by a commissioning engineer and remote machine startup.

A modern balancing machine is complex equipment, and in conditions of a shortage of qualified personnel, high-quality specialist training is especially important. Therefore, we provide assistance in personnel training. During the training of a balancing machine operator, skills for working with the machine and the principles of rotor dynamic balancing are transferred.

An excellent reference tool for the machine operator is the "Balance Guide: Multimedia Course for Preparation to Work on a Balancing Machine" program. The media course consists of a series of videos that provide a brief description of terms used in the balancing process, describe types of rotors, causes and types of imbalance, main correction methods, outline safety measures when working with the machine, principles of interaction with the machine components, and describe all the functions of the software that controls the balancing machine.

The program can be used to review knowledge acquired during the commissioning works.