Any Balancing Machines Modernization

Balancing machines are often used for ten or more years. Physical wear and tear, along with the technological obsolescence of components and assemblies, prevents the rotor dynamic balancing machine from being used to balance rotors with the required accuracy. To restore the precision characteristics and functionality of the balancing machine, as well as to increase productivity, modernization is necessary. This includes: updating the measurement and control system, as well as replacing worn components and parts. Furthermore, a significant portion of balancing machines produced in the 70s-90s have a DC drive, which is also subject to wear. We replace the DC drive with a modern frequency-controlled asynchronous drive.

The cost of modernization is significantly less than the cost of purchasing new balancing equipment. Often, companies purchase used balancing machines and modernize them, which is economically feasible.

The most in-demand services are the modernization of the mechanical and electronic parts of the balancing machine. Balancing systems fail due to physical wear of mechanical elements, and the electronic part becomes obsolete. By replacing them, we typically achieve precision characteristics higher than those of a comparable new machine, ready to serve for many years.

Three main areas of modernization for horizontal balancing machines can be distinguished: modernization of the mechanical, electronic, and electrical parts of the machine.

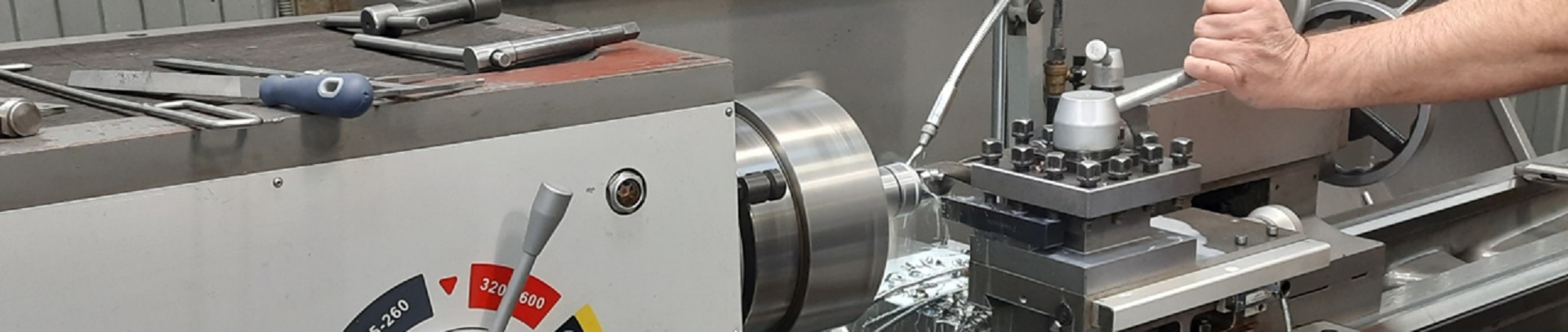

- Modernization of the mechanical part: inspection of bearings and damaged units, replacement of the tension system and rotor drive, repainting.

- Modernization of the electrical part: replacement of the drive unit electric motor, vibration sensors, rotor angular position sensor (encoder), laser tachometer, frequency converter, safety systems.

- Modernization of the electronic part: replacement of the measurement and control system for the balancing machine.

The electronic modernization kit includes the "R-Bal SI-1" measurement system with vibration sensors, a laser tachometer, and an incremental encoder.

The "R–Bal SI–1" measurement system is included in the unified register of measuring instruments and can be metrologically verified. "R-Bal SI-1" is designed to work with all types of machines: sub-resonant, super-resonant, horizontal, vertical, and on each of them, it provides precision accuracy in unbalance measurement.

The balancing software has an intuitive and user-friendly interface, allowing the operator to learn how to operate the machine in the shortest possible time and obtain measurement results as quickly as possible.

On sub-resonant machines, the "R–Bal SI–1" system allows for determining unbalance on the first start of the rotor — this significantly reduces the total balancing time and eliminates the need for several calibration runs to determine influence coefficients, which is especially important for rotors with a high level of initial unbalance. Interaction with the measurement system can be done either via a touch screen monitor or a keyboard and mouse. The control cabinet includes a compartment for installing a printer, storing tools, drive belts, and other accessories.

MAIN REASONS FOR MODERNIZING BALANCING MACHINES

-

It makes sense to modernize a balancing machine when the following signs appear:

- Insufficient machine accuracy, which manifests as the inability to balance a product within the required permissible unbalance tolerance.

- Insufficient productivity of the balancing machine, which manifests as an increase in the number of balancing runs required to achieve the permissible unbalance, and the lack of necessary software functions to increase productivity.

- Insufficient technological capabilities, which manifest as the absence of necessary devices for balancing rotors, such as counter-supports, alternative drive devices, drilling and welding units.

- The main advantages of modernizing a horizontal balancing machine compared to buying new equipment are lower cost and significantly shorter lead times.

Thanks to its fleet of metalworking equipment, the company "Robals" can restore horizontal balancing machines for dynamic balancing that have been out of service for a long time and have significant damage or missing parts. Modernization work on balancing machines is carried out either entirely by "Robals" specialists or shared with the Customer.